ಕೇಬಲ್-ರೂಪಿಸುವ ಯಂತ್ರಗಳನ್ನು ಸಾಮಾನ್ಯವಾಗಿ ಎರಡು ವಿಧಗಳಾಗಿ ವಿಂಗಡಿಸಬಹುದು: ಕೇಜ್ ಕೇಬಲ್-ರೂಪಿಸುವ ಯಂತ್ರಗಳು ಮತ್ತು ಹೆಚ್ಚಿನ ವೇಗದ ಕೇಜ್ ಕೇಬಲ್-ರೂಪಿಸುವ ಯಂತ್ರಗಳು. ಅವುಗಳಲ್ಲಿ, ಹೈ-ಸ್ಪೀಡ್ ಕೇಜ್ ಕೇಬಲ್-ರೂಪಿಸುವ ಯಂತ್ರವನ್ನು ತಾಮ್ರದ-ಕೋರ್ ಅಲ್ಯೂಮಿನಿಯಂ ಸ್ಟ್ರಾಂಡೆಡ್ ತಂತಿಗಳು ಮತ್ತು ಬೇರ್ ಅಲ್ಯೂಮಿನಿಯಂ ತಂತಿಗಳ ಸ್ಟ್ರಾಂಡಿಂಗ್ಗಾಗಿ ಬಳಸಲಾಗುತ್ತದೆ. ಏತನ್ಮಧ್ಯೆ, ಪ್ಲಾಸ್ಟಿಕ್ ಪವರ್ ಕೇಬಲ್ಗಳು, ರಬ್ಬರ್-ಹೊದಿಕೆಯ ಕೇಬಲ್ಗಳು ಮತ್ತು ಇತರ ಉತ್ಪನ್ನಗಳ ಕೇಬಲ್-ರೂಪಿಸುವಿಕೆಗೆ ಸಹ ಇದನ್ನು ಬಳಸಬಹುದು.

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳ ಪರಿಚಯ

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳನ್ನು ಸಾಮಾನ್ಯವಾಗಿ ಎರಡು ವಿಧಗಳಾಗಿ ವಿಂಗಡಿಸಬಹುದು: ಕೇಜ್ ಪ್ರಕಾರದ ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳು ಮತ್ತು ಹೆಚ್ಚಿನ ವೇಗದ ಕೇಜ್ ಮಾದರಿಯ ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳು. ಅವುಗಳಲ್ಲಿ, ಹೈ-ಸ್ಪೀಡ್ ಕೇಜ್ ಟೈಪ್ ಕೇಬಲ್ ಲೇಯಿಂಗ್-ಅಪ್ ಯಂತ್ರವನ್ನು ತಾಮ್ರದ ಹೊದಿಕೆಯ ಅಲ್ಯೂಮಿನಿಯಂ ಸ್ಟ್ರಾಂಡೆಡ್ ತಂತಿಗಳು ಮತ್ತು ಬೇರ್ ಅಲ್ಯೂಮಿನಿಯಂ ತಂತಿಗಳನ್ನು ಜೋಡಿಸಲು ಬಳಸಲಾಗುತ್ತದೆ ಮತ್ತು ಪ್ಲಾಸ್ಟಿಕ್ ಪವರ್ ಕೇಬಲ್ಗಳ ಕೇಬಲ್ ಹಾಕಲು, ರಬ್ಬರ್ ಹೊದಿಕೆಗೆ ಸಹ ಬಳಸಬಹುದು. ಕೇಬಲ್ಗಳು ಮತ್ತು ಇತರ ಉತ್ಪನ್ನಗಳು.

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳ ಅಪ್ಲಿಕೇಶನ್

ಈ ಉತ್ಪನ್ನಗಳ ಸರಣಿಯು ಬಹು-ಕೋರ್ ರಬ್ಬರ್ ಕೇಬಲ್ಗಳು, ರಬ್ಬರ್ ಕೇಬಲ್ಗಳು, ಸಿಗ್ನಲ್ ಕೇಬಲ್ಗಳು, ಪ್ಲಾಸ್ಟಿಕ್ ಪವರ್ ಕೇಬಲ್ಗಳು, ಕ್ರಾಸ್-ಲಿಂಕ್ಡ್ ಕೇಬಲ್ಗಳು, ಟೆಲಿಫೋನ್ ಕೇಬಲ್ಗಳು, ಕಂಟ್ರೋಲ್ ಕೇಬಲ್ಗಳು ಇತ್ಯಾದಿಗಳಿಗೆ ಕೇಬಲ್ ಹಾಕುವ ತಯಾರಕರಿಗೆ ವಿವಿಧ ಅಡ್ಡ-ವಿಭಾಗಗಳೊಂದಿಗೆ ಸೂಕ್ತವಾಗಿದೆ.

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳ ವೈಶಿಷ್ಟ್ಯಗಳು

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳ ಈ ಸರಣಿಯು ಕೇಬಲ್ ಉತ್ಪಾದನೆಗೆ ಅಗತ್ಯವಾದ ಸಾಧನವಾಗಿದೆ. ಉಪಕರಣವು ವಿವಿಧ ವಿಧಗಳು ಮತ್ತು ಸಂಪೂರ್ಣ ವಿಶೇಷಣಗಳನ್ನು ಹೊಂದಿದೆ ಮತ್ತು ವ್ಯಾಪಕವಾಗಿ ಅನ್ವಯಿಸುತ್ತದೆ. ಬಳಕೆದಾರರು ತಮ್ಮ ಸ್ವಂತ ಉತ್ಪಾದನಾ ಉತ್ಪನ್ನಗಳ ಅಗತ್ಯಗಳಿಗೆ ಅನುಗುಣವಾಗಿ ಅನುಗುಣವಾದ ಕೇಬಲ್ ಹಾಕುವ ಸಾಧನವನ್ನು ಆಯ್ಕೆ ಮಾಡಬಹುದು. ಉಪಕರಣವು ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್ ಮತ್ತು ರಿವರ್ಸ್ ಅಲ್ಲದ ತಿರುಚುವಿಕೆಯ ಕಾರ್ಯಗಳನ್ನು ಹೊಂದಿದೆ. ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್ ವಿಧಾನಗಳಲ್ಲಿ ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್ ರಿಂಗ್ ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್, ಪ್ಲಾನೆಟರಿ ಗೇರ್ ಟ್ರೈನ್ ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್ ಮತ್ತು ಸ್ಪ್ರಾಕೆಟ್ ರಿವರ್ಸ್ ಟ್ವಿಸ್ಟಿಂಗ್ ಸೇರಿವೆ. ಪೂರ್ವ-ತಿರುಗುವ ರೂಪಗಳನ್ನು ಹಸ್ತಚಾಲಿತ ಪೂರ್ವ-ತಿರುಗುವಿಕೆ ಮತ್ತು ವಿದ್ಯುತ್ ಪೂರ್ವ-ತಿರುಚಿ ಎಂದು ವಿಂಗಡಿಸಲಾಗಿದೆ. ವೈರ್ ಸ್ಪೂಲ್ ಕ್ಲ್ಯಾಂಪಿಂಗ್ ಅನ್ನು ಹಸ್ತಚಾಲಿತ ಕ್ಲ್ಯಾಂಪಿಂಗ್ ಮತ್ತು ಎಲೆಕ್ಟ್ರಿಕ್ ಕ್ಲ್ಯಾಂಪಿಂಗ್ ಎಂದು ವಿಂಗಡಿಸಲಾಗಿದೆ. ಟೇಕ್-ಅಪ್ ಅನ್ನು ಶಾಫ್ಟ್ ಮತ್ತು ಶಾಫ್ಟ್ಲೆಸ್ ರೂಪಗಳಾಗಿ ವಿಂಗಡಿಸಲಾಗಿದೆ.

ಸಲಕರಣೆ ಸಂಯೋಜನೆ

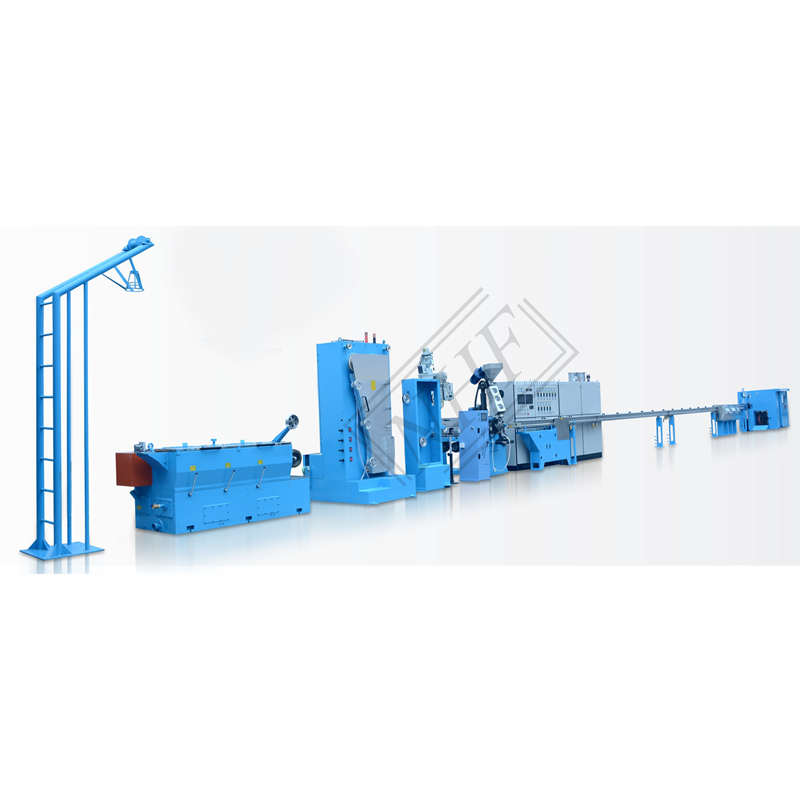

ಪೇ-ಆಫ್ ರ್ಯಾಕ್, ಸ್ಟ್ರಾಂಡಿಂಗ್ ಕೇಜ್ ಬಾಡಿ, ವೈರ್ ಡೈ ಹೋಲ್ಡರ್, ಲ್ಯಾಪಿಂಗ್ ಮೆಷಿನ್, ಆರ್ಮರಿಂಗ್ ಮೆಷಿನ್, ಲೆಂಗ್ತ್ ಕೌಂಟರ್, ಟ್ರಾಕ್ಷನ್ ಡಿವೈಸ್, ಟೇಕ್-ಅಪ್ ಮತ್ತು ಲೇಯಿಂಗ್-ಅಪ್ ರ್ಯಾಕ್, ಟ್ರಾನ್ಸ್ಮಿಷನ್ ಸಿಸ್ಟಮ್ ಮತ್ತು ಎಲೆಕ್ಟ್ರಿಕಲ್ ಸಿಸ್ಟಮ್.

ಮುಖ್ಯ ತಾಂತ್ರಿಕ ನಿಯತಾಂಕಗಳು

- ಕೇಬಲ್ ಹಾಕುವ ಅಡ್ಡ-ವಿಭಾಗ

- ಸ್ಟ್ರಾಂಡಿಂಗ್ ಕೇಜ್ ತಿರುಗುವ ವೇಗ

- ಕೇಬಲ್ ಹಾಕುವ ಪಿಚ್

- ಲ್ಯಾಪಿಂಗ್ ಹೆಡ್ ತಿರುಗುವ ವೇಗ

- ಲ್ಯಾಪಿಂಗ್ ಪಿಚ್

- ಎಳೆತ ಚಕ್ರದ ವ್ಯಾಸ

- ಔಟ್ಲೆಟ್ ತಂತಿ ವೇಗ

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳ ವಿಧಗಳು

ಕೇಬಲ್ ಹಾಕಲು ಬಳಸುವ ಉಪಕರಣಗಳು, ಅಂದರೆ, ಇನ್ಸುಲೇಟೆಡ್ ವೈರ್ ಕೋರ್ಗಳನ್ನು ಒಟ್ಟಿಗೆ ತಿರುಗಿಸುವ ಮತ್ತು ಭರ್ತಿ ಮಾಡುವ ಮತ್ತು ಲ್ಯಾಪಿಂಗ್ ಮಾಡುವ ಉಪಕರಣವನ್ನು ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರ ಎಂದು ಕರೆಯಲಾಗುತ್ತದೆ. ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳನ್ನು ಸಾಮಾನ್ಯ ವಿಧ ಮತ್ತು ಡ್ರಮ್ ಸ್ಟ್ರಾಂಡಿಂಗ್ ಪ್ರಕಾರವಾಗಿ ವಿಂಗಡಿಸಲಾಗಿದೆ. ಸಾಮಾನ್ಯ ವಿಧದ ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳು ಕೇಜ್ ಪ್ರಕಾರ ಮತ್ತು ಡ್ರಮ್ ಪ್ರಕಾರವನ್ನು ಒಳಗೊಂಡಿರುತ್ತವೆ ಮತ್ತು ಕೇಬಲ್ ಹಾಕುವ ವೇಗವು ಸಾಮಾನ್ಯವಾಗಿ 10m/min ಗಿಂತ ಕಡಿಮೆಯಿರುತ್ತದೆ. ದೊಡ್ಡ ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳನ್ನು ಡ್ರಮ್ ಪ್ರಕಾರವಾಗಿ ತಯಾರಿಸಲಾಗುತ್ತದೆ ಮತ್ತು ಮೂರು-ಕೋರ್, ನಾಲ್ಕು-ಕೋರ್ ಮತ್ತು ಐದು-ಕೋರ್ ಕೇಬಲ್ಗಳ ಕೇಬಲ್ ಹಾಕುವಿಕೆಯನ್ನು ನಿರ್ವಹಿಸಬಹುದು. ಉದಾಹರಣೆಗೆ, 1 + 3/1600 ಮತ್ತು 1 + 3/2400, 1 + 4/1600, 1 + 4/2400 ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳು ಮತ್ತು ಗರಿಷ್ಠ ಪೇ-ಆಫ್ ರೀಲ್ಗಳು ಕ್ರಮವಾಗಿ 1600mm ಮತ್ತು 2400mm. ಮಧ್ಯಮ ಮತ್ತು ಸಣ್ಣ ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳನ್ನು ಕೇಜ್ ಪ್ರಕಾರವಾಗಿ ತಯಾರಿಸಲಾಗುತ್ತದೆ ಮತ್ತು ಸ್ಟ್ರಾಂಡಿಂಗ್ ಭಾಗವು ವೈರ್ ಸ್ಟ್ರಾಂಡಿಂಗ್ ಯಂತ್ರದ ಸ್ಟ್ರಾಂಡಿಂಗ್ ಕೇಜ್ನಂತಿದೆ, ವಿಶೇಷಣಗಳು ಮತ್ತು ಫಾರ್ಮ್ಗಳಾದ 1 + 6/1000 ಮತ್ತು 1 + 6/400. ಡ್ರಮ್ ಸ್ಟ್ರಾಂಡಿಂಗ್ ಪ್ರಕಾರದ ಕೇಬಲ್ ಲೇಯಿಂಗ್-ಅಪ್ ಯಂತ್ರವು ಹೆಚ್ಚಿನ ಉತ್ಪಾದನಾ ದಕ್ಷತೆ ಮತ್ತು ಸಾಮಾನ್ಯವಾಗಿ 30m/min ಗಿಂತ ಹೆಚ್ಚಿನ ವೇಗವನ್ನು ಹೊಂದಿರುವ ತುಲನಾತ್ಮಕವಾಗಿ ಹೊಸ ಕೇಬಲ್ ಹಾಕುವ ಸಾಧನವಾಗಿದೆ. ಇದು ವ್ಯಾಪಕವಾದ ಅಪ್ಲಿಕೇಶನ್ ಶ್ರೇಣಿಯನ್ನು ಹೊಂದಿದೆ ಮತ್ತು ವಿವಿಧ ವಿದ್ಯುತ್ ಕೇಬಲ್ಗಳ ಕೇಬಲ್ ಹಾಕುವಿಕೆಗೆ, ಹಾಗೆಯೇ ಸಂವಹನ ಕೇಬಲ್ಗಳ ಕೇಬಲ್ ಸ್ಟ್ರಾಂಡಿಂಗ್, ನಿಯಂತ್ರಣ ಕೇಬಲ್ಗಳು ಮತ್ತು ದೊಡ್ಡ-ವಿಭಾಗದ ಅಲ್ಟ್ರಾ-ಹೈ ವೋಲ್ಟೇಜ್ ಕೇಬಲ್ ಸ್ಪ್ಲಿಟ್ ಕಂಡಕ್ಟರ್ಗಳಿಗೆ ಬಳಸಬಹುದು.

ಕೇಬಲ್ ಹಾಕುವ ಯಂತ್ರಗಳಲ್ಲಿ ಆವರ್ತನ ಪರಿವರ್ತಕಗಳ ಅಪ್ಲಿಕೇಶನ್

ಪಾವತಿ ವ್ಯವಸ್ಥೆ

ಪೇ-ಆಫ್ ರ್ಯಾಕ್ 12 ನಿಷ್ಕ್ರಿಯ ಪೇ-ಆಫ್ ಘಟಕಗಳಿಂದ ಕೂಡಿದೆ. ಪೇ-ಆಫ್ ಟೆನ್ಷನ್ ಅನ್ನು ಪೇ-ಆಫ್ ರೀಲ್ನ ತಿರುಗುವ ಶಾಫ್ಟ್ನ ವಿರುದ್ಧ ಉಕ್ಕಿನ ಪಟ್ಟಿಯ ಘರ್ಷಣೆಯಿಂದ ತಂತಿಯ ನಿಷ್ಕ್ರಿಯ ಟೆನ್ಷನ್ ಪೇ-ಆಫ್ ಅನ್ನು ಅರಿತುಕೊಳ್ಳಲಾಗುತ್ತದೆ.

ಎಳೆತ ವ್ಯವಸ್ಥೆ

ಮಲ್ಟಿ-ಸ್ಟ್ರಾಂಡ್ ವೈರ್ಗಳು ಮತ್ತು ಬೆಲ್ಟ್ ಪ್ರೆಶರ್ ರೋಲರ್ಗಳನ್ನು ಎಳೆತಕ್ಕಾಗಿ ಸಿಸ್ಟಮ್ ಸ್ಪೀಡ್ ಸೆಟ್ಟಿಂಗ್ ಮತ್ತು ಸಿಸ್ಟಮ್ ಸ್ಪೀಡ್ ರೆಫರೆನ್ಸ್ ಅನ್ನು ಅರಿತುಕೊಳ್ಳಲು ಬಳಸಲಾಗುತ್ತದೆ. ಆವರ್ತನ ಪರಿವರ್ತಕವು RS485 ಸಂವಹನ ಇಂಟರ್ಫೇಸ್ ಮೂಲಕ PLC ಗೆ ವೇಗದ ಪರಿಣಾಮಕಾರಿ ಮೌಲ್ಯವನ್ನು ನೀಡುತ್ತದೆ. PLC ಸ್ಟ್ರಾಂಡಿಂಗ್ ಬಿಲ್ಲು ಮತ್ತು ಟೇಕ್-ಅಪ್ ಯಂತ್ರ ಚಾಲಕದ ಡೇಟಾವನ್ನು ಪ್ರಕ್ರಿಯೆಗೊಳಿಸಿದ ನಂತರ, ಇದು RS485 ಇಂಟರ್ಫೇಸ್ ಮೂಲಕ ಸ್ಟ್ರಾಂಡಿಂಗ್ ಬಿಲ್ಲು ಮತ್ತು ಟೇಕ್-ಅಪ್ ಡ್ರೈವರ್ಗೆ ಡೇಟಾವನ್ನು ಔಟ್ಪುಟ್ ಮಾಡುತ್ತದೆ.

ನರ್ತಕಿ

ವೈರ್ ಗೈಡ್ ಚಕ್ರದ ಮೂಲಕ ಹಾದುಹೋಗುವ ತಂತಿಯ ಕೌಂಟರ್ ವೇಟ್ ಅನ್ನು ಸರಿಹೊಂದಿಸುವ ಮೂಲಕ ಅಥವಾ ಏರ್ ಸಿಲಿಂಡರ್ನ ಗಾಳಿಯ ಒತ್ತಡವನ್ನು ಸರಿಹೊಂದಿಸುವ ಮೂಲಕ ತಂತಿ ಒತ್ತಡವನ್ನು ಸರಿಹೊಂದಿಸಲಾಗುತ್ತದೆ. ಟೇಕ್-ಅಪ್ ಯಂತ್ರದ ಟೇಕ್-ಅಪ್ ಪ್ರಕ್ರಿಯೆಯಲ್ಲಿ, ಅಂಕುಡೊಂಕಾದ ವ್ಯಾಸದ ಬದಲಾವಣೆಯಿಂದ ಉಂಟಾದ ಟೇಕ್-ಅಪ್ ಯಂತ್ರದ ಟೇಕ್-ಅಪ್ ವೇಗದ ಬದಲಾವಣೆಯನ್ನು ಸರಿಹೊಂದಿಸಲು ನರ್ತಕಿ ಸ್ಥಾನದ ಬದಲಾವಣೆಯನ್ನು PLC ಗೆ ಕಳುಹಿಸಲಾಗುತ್ತದೆ. ಸ್ಥಿರ ರೇಖೀಯ ವೇಗ ಮತ್ತು ನಿರಂತರ ಒತ್ತಡದ ಅಂಕುಡೊಂಕಾದ ನಿಯಂತ್ರಣವನ್ನು ಅರಿತುಕೊಳ್ಳುವಂತೆ.

ಪೋಸ್ಟ್ ಸಮಯ: ನವೆಂಬರ್-28-2024